Sitting alone at the ends of your doctor blade chambers, are rarely thought of, yet vital and inexpensive consumables that have a direct impact on the quality of every job you run: your end seals.

About now you’re thinking, “End seals? I don’t think about them or replace them until they leak.”

While you’re probably not the only person with that line of thought, Provident technical sales reps continually hear about leaking end seals from press operators and business owners alike. It turns out that leaking seals are a common, yet under-the-radar, concern and that generic seals are rarely the best answer. In the big picture, it’s a matter of eliminating one more variable that can have a direct impact on costs, productivity and print quality. Up-close and on your production line, it’s the details that matter.

Imagine, for instance, you are producing some colorful labels or packaging. Suddenly, halfway through a two-up 66,000-foot run, you begin seeing drops of yellow, matching that nice spot color your customer specified, on the right side of the roll, hitting about every third image. The pressman hits stop and everything comes to a screeching halt.

You quickly trace the leak to a bad end seal on one of the spot color ink supplies and find that over 9,000 feet of substrate has been hit by the yellow with another 4,000 feet hit with occasional drops of brilliant yellow. You replace the bad seal and wonder if you should do all of them while the press is down. Still, whether you re-run the whole job or just enough to make up for the loss, this is not shaping up to be a good day.

When seals go bad

End seals can fail in a little drip, drip, drip way, a spectacular one that empties a pressurized ink chamber faster than you can say blow out, or anywhere in between. But no matter how it happens, ink going places it doesn’t belong presents a problem you and your press operators have to deal with immediately. And no matter the extent of the leak, it costs time, labor, material and productivity.

End seals fail for a variety of reasons. Although they are static parts of a press, they are still subject to wear from doctor blades, anilox rolls and are subject to drying out and simply age—this is why seals are considered consumables. No end seal will last indefinitely, but what matters is whether it fits properly and can provide a reasonable life span so you can work with less worry about failure of an inexpensive part ruining several thousand dollars’ worth of labels or packaging.

Better seals

Every press comes with end seals installed, but just as the tires on your new car are probably not the best on the market, the stock seals are not necessarily the best available. In evaluating presses, we often see seals that are flattened from prolonged use, dried out, and either leaking or on the verge of significant failure.

So what do you do?

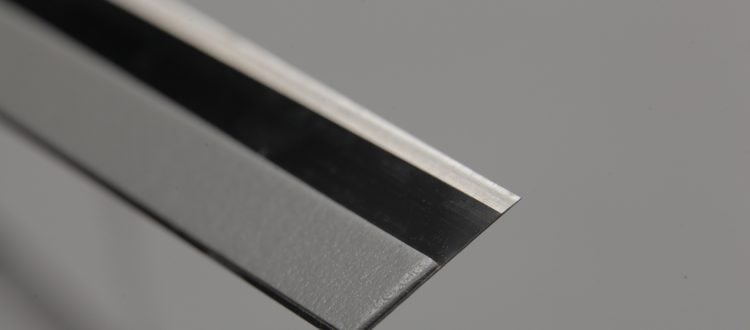

Ink systems are our stock and trade at Provident. We know the weak points in flexo presses and how to ease the worry about doctor blades, chamber pressures, back doctoring, and end seals. One of our most popular approaches is custom seals. This is not an exotic or over-the-top approach and actually makes sense. Here’s why: every press—and its seals—change over time. Some dry out, some deform, and stock ones may not fit so well after the new wears off the press. The result is leaks large and small. In our years of going into shops of all sizes we have found that custom seals made for a specific press is best way to provide the confidence needed to run any job and reduce worry about end seal leaks. After our technical sales reps take the necessary measurements on your presses, we use water jets to custom cut the most appropriate material to create tight-fitting, durable end seals for the ink chambers on any press in your shop.

Not sure this is right for you? No problem. We can create a one-off set of custom seals so you can judge for yourself the advantages of custom end seals. Contact your Provident Technical Sales Rep to learn more about how custom end seals can remove one more variable from your label and package printing operation.