What do you see when you watch a flexo press run? Do you see the entire, almost magical, process of turning a clear sheet of material into a flexible package or label that shimmers with color? Do you look at the processes taking place on each deck as the colors are precisely metered to ensure each image is just what the brand owner expects?

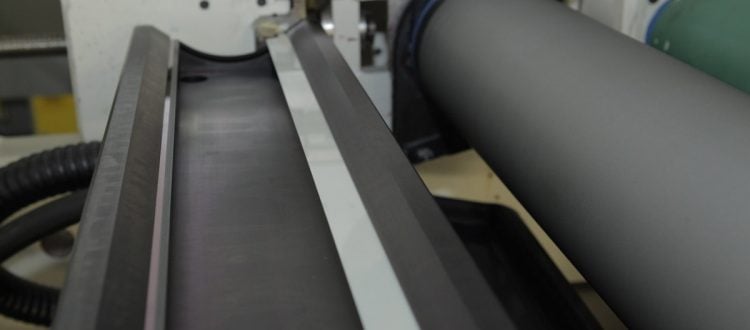

Yet, as you watch, you may not be paying much attention to two parts that ultimately make it all possible—the anilox rolls and doctor blades. But you should, because these components account for a significant portion of a press’s operating cost and the value it delivers for your company and your customers. Remember, anilox rolls still are the “heart of a flexo press.”

Tooling Costs

This is because image quality depends on anilox rolls consistently delivering a precise volume of ink run after run. This control doesn’t come cheap. For example, a single 8- or 10-color CI press requires at least twice as many anilox rolls as it has colors, because most shops have at least one back up for every roll on the press. That total investment can easily exceed $100,000 plus an additional 20 percent of that amount for a year’s supply of doctor blades. In all, tooling for a single press can exceed $100,000 initially, around $20,000 for recovering worn rollers, and $20,000 annually for doctor blades.

These numbers are more than a cost of doing business. And it is a figure under assault by companies that seem more interested in selling a product than helping you succeed. But why? How?

Because your choice of doctor blades really matters. You already know blades influence the quality of the labels and packages you print. And, because we’re in the business of providing the best performing, longest lasting doctor blades on the market, we take pride in helping you produce superior quality work for your customers, but not at the expense of the heart of your flexo press.

The thing is, doctor blades are not all created equal no matter what their promoters may claim. We’ve talked in this blog several times about the value of high quality doctor blades and the importance of using blades that are compatible with your anilox rolls because the heart of your press is not a place for a random assemblage of parts. Yet, we have roll vendors telling us they are seeing accelerated wear on rolls that believe is primarily due to the choice of doctor blades.

What We’re Hearing

Over the past few months, several leading anilox roll makers tell us they have seen increased demand for roll re-surfacing or even entirely new rolls, apparently as a result of customers choosing doctor blades claimed to offer long working lives. They bring this to our attention because we promote some of our blades as offering greater durability and having longer working lives, so the roll makers are doing some due diligence. As well they should.

What they are finding is that print shops using our blades are not having the same experience as those using long life doctor blades from other suppliers. This is because our doctor blades are not inflicting unusual or excessive wear on costly anilox rolls.

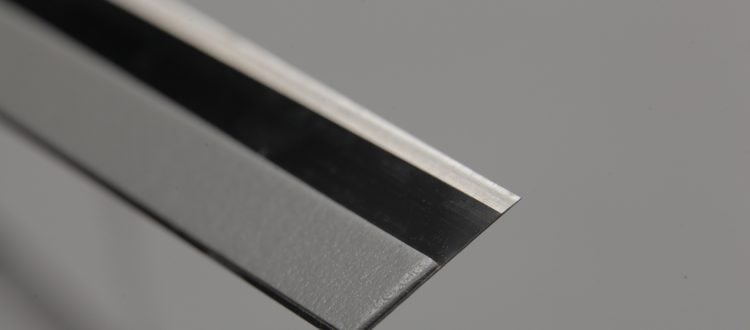

The key difference is in the how the blades are made. It’s obvious that harder the blade, the longer it will last. But there’s a limit to how hard a blade should be because while the ceramic coating on an anilox roll provides a very hard surface, the steel doctor blade is in constant contact with that surface. A blade that’s harder than the ceramic will wear more slowly while the ceramic wears at a faster rate. This results in an expensive anilox roll needing refinishing or replacing sooner because the chosen “long life” doctor blade is too hard.

To show the false economy here, let’s revisit the tooling cost on an 8- or 10-color CI press. The $100,000 worth of anilox rolls is based on 20 rolls on a 10-color press at a cost of about $5,000 per new roll. So if all the rolls have to be replaced annually you get to fork out another 100-Large. Even if you can get by with re-surfacing all of them (at about $3,500 each) it’s still around $70-grand you can probably find better uses for.

The Internal Disconnect

We know, from being in hundreds of shops of all sizes around North America, that the people who order doctor blades are not necessarily the same people who sign the purchase orders for anilox rolls. Beyond that, these different people don’t always talk with each other. As a result, there may not be many folks at a given print provider who can make the connection between decreased doctor blade consumption, increased spending on anilox rolls, and what happens on press when worn rolls are used.

Meanwhile, the spend for a monthly consumable—doctor blades—is declining, which can be seen as good, while an increase in spending for anilox roll resurfacing or replacement, not necessarily being a monthly cost, is less obvious. OK, someone in a plant—perhaps a hands-on owner, an engineer or sharp-eyed accountant—probably notices the anilox expense is going up, but not question why. It may be chalked up to business being good, or older rolls simply reaching end of life. But because of the internal disconnect in the ordering processes no one realizes that incorrect doctor blade choices are causing anilox rolls to be eaten alive, costing the operation money.

Addressing the Problem

There are ways to address this. First is to have your anilox rolls evaluated so you know what their actual cell capacities really are and to get a sense out of how much practical life is left in each roll. One way to do this is by using a tool called the Troika AniCAM, which provides microphotographs of the cells in your rolls and provides a real-time status of each one.

Next, make sure the doctor blades you use are truly compatible with your rolls. You want blades that are slightly softer than the ceramic coating so the blade—an inexpensive consumable—will wear faster than the roll. This way you replace a blade instead of a pricey, highly engineered, laser engraved, and ceramic-coated anilox roll.

At Provident, we’re ink system professionals who can help you better understand the nuances of your many job requirements and define and deliver the optimal solutions for your business. Contact us with any questions or concerns. We’re here to help you succeed.