Way back in shop class, this was probably middle school, the teacher used to say something like “Measure twice, cut once,” usually followed by the reminder that you can “always cut off, but you can’t add on.” The words probably made an impression because some echo of them still rattle around in your brain case every time you cut a piece of wood or metal or plastic on a home improvement project.

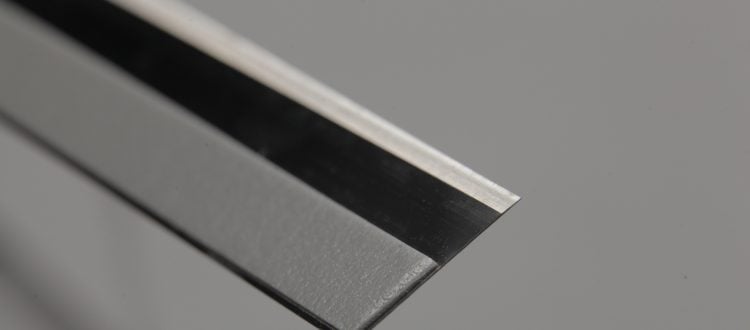

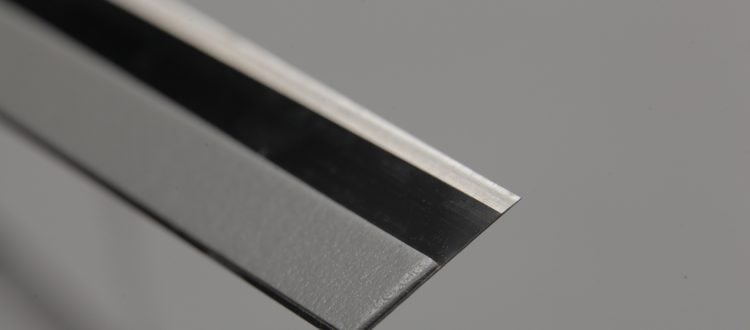

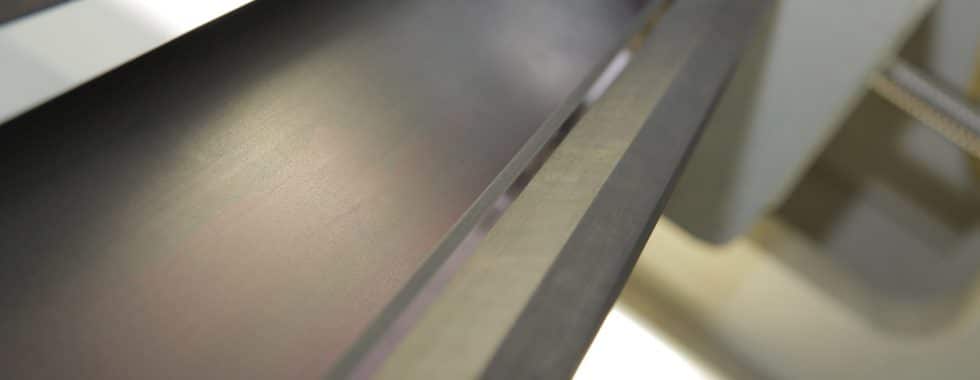

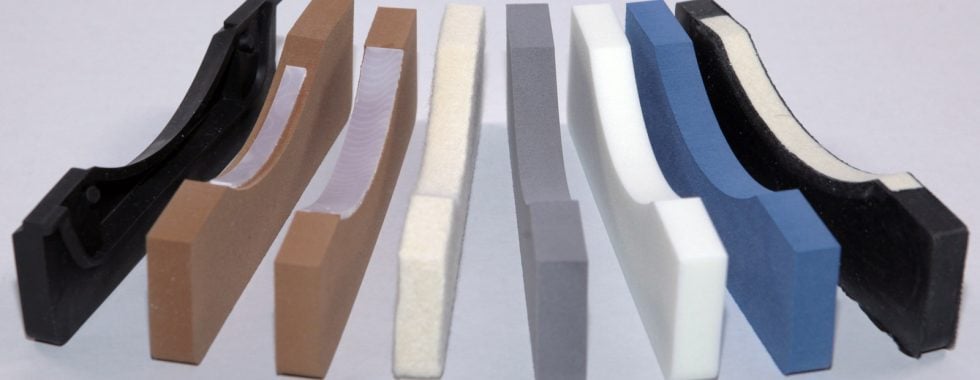

Fast forward to today where a few flexo presses take up real estate on your shop floor. We talked last time about making sure your doctor blades are the correct length to minimize leaks and excessive consumption of blade material. Still, even if you verified the exact size blade you needed and measured twice before cutting or ordering the effort can be wasted if you aren’t specifying the right type of blade to begin with. Like so many other things about these seemingly innocuous strips of steel, plastic or polyester laminate than are readily apparent, you absolutely must use the right type of blade for every job.

Do the math

For example, some shops have a practice of using a specific press (and blades) for running white inks because the abrasive characteristics of the titanium in white inks wears blades and other components faster. Although coated blades that can handle this added wear are readily available, some shops don’t spend the extra few dollars to use those blades on their white decks. This is shortsighted because while it seems less expensive to buy standard blades it can actually be more expensive because they have to be replaced more often, especially on decks running titanium inks. When you do the numbers and compare the cumulative costs of continually replacing normal blades versus the longer lifespan of coated ones, it is clear that you can be laying out money you don’t need to spend. Furthermore, extra blade changes take your press offline when it could be productive, adding to the cost of the “less expensive” blades.

Distorting reality

Also distorting reality are some of the blade evaluation forms provided by many blade suppliers. Some forms are very basic, but whenever possible use—and refer to—the most detailed versions of the forms available. Then ask questions, not just about the blades you have or are considering, but in the context of other products in your facility. For instance, the forms may show that blade choices are influencing anilox roll wear or poor metering, factors that may not be immediately attributed to blade selection.

On a related note, get into the habit of measuring blade wear and life consistently across all your presses. Be smart about this because they won’t all be the same, but by using a consistent means of measurement, something as basic as placing counters on all presses, can provide a metric for blade changing that you can refer back to or revise. What you should not do, however, is blithely assume that all blades should be changed at X-thousand feet. Such one-size-fits-all thinking results in some blades being changed too early, while others can be run past their practical life. Both mistakes cost money. Many successful shops base blade changes on experience, such as how many feet have been run when using a specified substrate or type of ink (such as white). Some shops run certain types of jobs only on specific presses because it takes one more variable out of the process. This is a ‘work smarter, not harder’ approach that can make a lot of sense in a busy shop.

Where to begin

To get started, pick a couple of presses for testing and monitor the results over say, a three- or six-month period. Mount the counters and new, correctly sized doctor, metering and containment blades on each deck. Then document every job run: run lengths, types of inks, substrates used, and carefully track any other variables. Over the course of the test you will be able to identify and begin reducing inconsistencies. With that info in hand you can make changes that will help you run your shop more efficiently and better control and predict your costs.

It’s easy to think monitoring and tracking are being too compulsive, but it’s really a case where knowing more helps you run your business better. Nearly all the most successful shops we at Provident go into, know the details and nuances of every part of their operations. Customers tell us it doesn’t take long for small differences in work processes or low-dollar expenditures like doctor blades or end seals to turn into savings that show up on the bottom line. And these days, as good as your margins may be, making the bottom line better is just good business.