Graymills Pumps & Filters

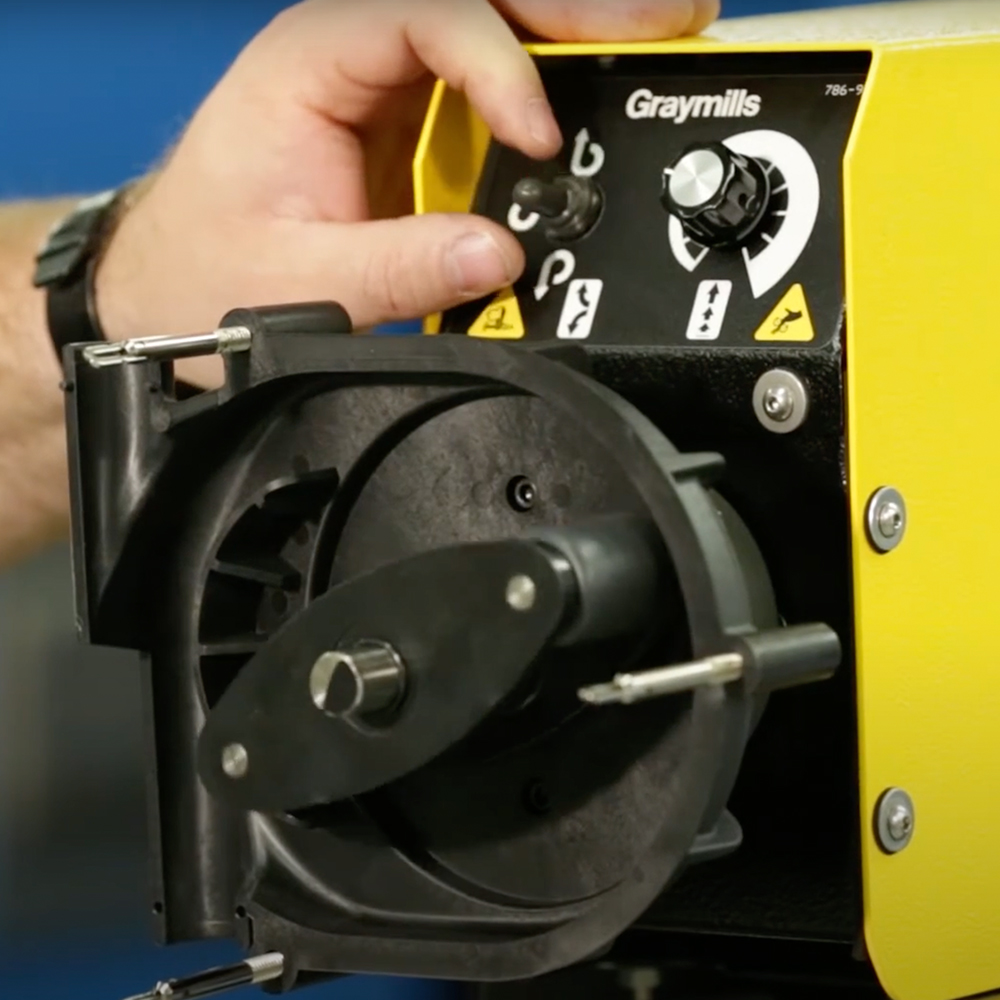

Peristaltic Pumps (a.k.a. Tube Pumps)

Steady Flow Centrifugal Pumps

Ink Filters

Graymills Superflo® filters are specially designed for flexographic and gravure ink systems, providing effective filtration to eliminate quality problems from contaminants that can also damage costly anilox rolls.

Rare Earth Filter Magnets

In a smooth stainless steel casing and 10x the pulling power of a standard magnet; megaMAG™ is able to attract metal particles from within the filter body or ink tank.

Why Choose Graymills Pumps & Filters?

The requirements of presses can vary significantly across flexo and gravure, which means that adaptability is crucial to minimizing downtime and boosting output.

For over 80 years, Graymills pumps and filters have been at the core of ink pumping, circulation, and conditioning. As an exclusive Graymills pump distributor, Provident offers a complete range of pump and filter solutions, including centrifugal pumps, peristaltic pumps, filter magnets and filters that help our customers ink and clean confidently.